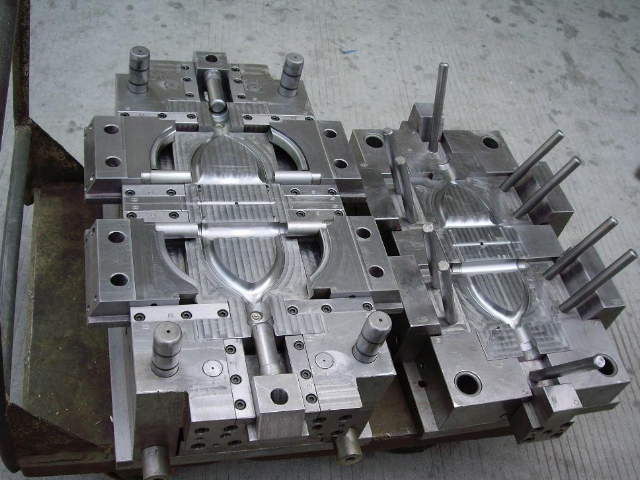

With the continuous development of the manufacturing industry, as an important tool for producing various products, the cleaning and maintenance of molds have become particularly important. Laser cleaning is a cleaning method that uses a high-energy laser beam to irradiate the surface of a mold, causing stains, rust, residues, etc. on the surface to evaporate and peel off instantly under the action of laser. This technology has the characteristics of non-contact, no grinding, and no thermal impact, so it will not affect the accuracy and surface quality of the mold. Traditional cleaning methods such as mechanical polishing and chemical cleaning have problems such as low efficiency and easy damage to molds. As an emerging cleaning technology, laser cleaning has been widely used in the field of mold cleaning due to its high efficiency and non-destructive advantages. This article will focus on exploring the application and advantages of laser cleaning in mold cleaning.

Removing surface stains on the mold: The high energy of the laser can quickly remove stains, oil stains, etc. attached to the surface of the mold without causing damage to the mold material itself.

Remove residues on the surface of the mold, such as plastic, glue, etc. Laser cleaning can quickly remove them without leaving any marks.

Removing rust on the surface of the mold: For difficult to remove rust, laser cleaning can achieve efficient and non-destructive removal.

Cleaning complex cavities: For cleaning complex cavities or small gaps, laser cleaning has significant advantages and can achieve results that traditional cleaning methods cannot achieve.

Compared to traditional polishing and pickling, laser cleaning has several advantages:

Efficient: Laser cleaning can quickly remove various stains, residues, and rust, greatly improving cleaning efficiency.

Non destructive: Laser cleaning is non-contact and will not cause scratches or damage to the surface of the mold.

Environmental protection: Laser cleaning does not require the use of any chemical reagents, reducing environmental pollution.

Wide application range: Whether it is metal molds or non-metal molds, laser cleaning can achieve good results.

High degree of automation: Combined with automation equipment, continuous operation can be achieved, greatly improving production efficiency.

Cost saving: Compared to traditional cleaning methods, laser cleaning can significantly reduce cleaning costs.

With the continuous progress of cleaning technology, more and more enterprises and researchers have realized the important role of laser cleaning in mold cleaning. Its advantages of high efficiency, non-destructive, and environmental friendliness have enabled it to achieve significant results in various complex and precise mold cleaning processes.